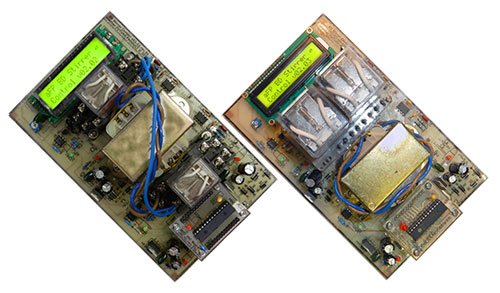

After a lot of hours and many a midnight candle burnt, testing design circuits and modifications to remove any issues when transitioning from a bread board style prototype to a printed circuit pre-commercial release (a.k.a. ‘Prototype #2’), the design was ready and VERSION 2 constructed and tested working in the field.

The design now includes built in timer and display with countdown to the stir finishing, the timer also continues after the stir so you are aware if getting back from the paddock after the 60 minute stir how long it has been finished.

The design is based on the same original idea of simplistic “logic control” and should work with most commonly available cap-start cap-run motors. Control has been made simple, and sensing from the stirrer is via a very simple and easily adjusted float/micro switch mechanism.

The control signals to the micro switch are low voltage and perfectly safe (unlike many existing implementations where high voltage is run through various fin/arm mechanisms inside the stirrer for motor control).

The high voltage cables to the motor for power supply and direction control use a proprietary connector and cable which needs to be wired by a qualified professional according to the design specifications. This only needs to be done once with the supplied cable and you should get a lifetime from the control unit and the motor.

The design of the control unit achieves the lowest possible stress on the motor during direction change.

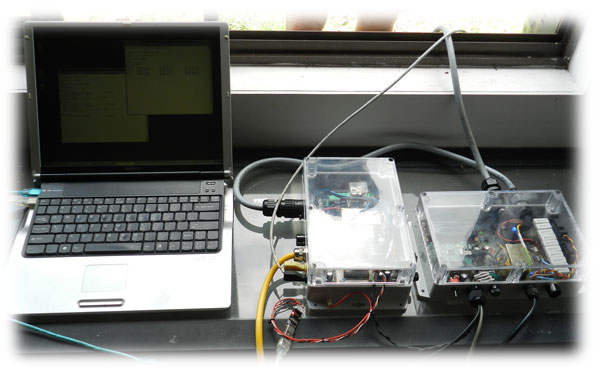

A test unit has also been produced to ensure each control unit produced meets performance expectations. Each new control unit produced is tested using a simulation mode in the lab for three separate hour long cycles.

They are then tested in the field using a pass-through mode on the test unit and connected to a stirrer with float micro switch mechanism. During all testing data is logged by the test unit and connected computer to determine there are no switching errors.

After final field testing units are certified for production, the current revision is suitable for 1HP motors typically used on single stirrers, but there has been a lot of interest in twin stirrers – and so research, prototyping, and further development and testing of the design is where we are at now..